|

Before Getting Started

It’s my position

that before you begin making sausages at home, you educate yourself about

matters of health and safety. Realize that by the time meat reaches

the butcher counter, it has gathered a number of different kinds of bacteria

just from handling. Some of these bacteria can cause severe gastrointestinal

consequences. Common bacteria like E. coli, Listeria sp. Salmonella sp. can

be easily transferred to the meat. You must learn how to discourage the

growth of harmful organisms in the ground meats you use for sausage making.

I found guidelines for the treatment of pork and pork products with regards

to health on the both USDA and Canadian Food Inspection Agency websites (see

links) to be very helpful. Always be careful to

prevent any further contamination and to always keep the temperature of the

meat low enough to discourage further bacterial growth. Keep the meat

refrigerated until its ready to be ground, and return it immediately to the

refrigerator as soon as possible.

Cleanliness is a major factor

in preventing food borne illness. Everything that touches food should be

clean. Kep the following steps in mind to help prevent food borne illness by

safely handling food in your home. You should wash your hands before and

after handling meat (especially uncooked raw meat, poultry, or fish and

their juices). Wash your hands (gloved or not) with warm, soapy water for 20

seconds with warm, soapy water. If your hands have any kind of skin abrasion

or infection, always use clean disposable gloves. and don't forget to was up

after blowing your nose, coughing, or sneezing.

Thoroughly wash all surfaces that come in contact with raw meat,

poultry, and fish with hot, soapy water, before moving on to sausage

preparation. Use paper towels to clean kitchen surfaces. If you use

dishcloths, wash them often in the hot cycle of your washing machine. Keep

other surfaces, such as faucets and counter tops, clean by washing with hot,

soapy water. To keep your knives and cutting boards clean, wash them in hot,

soapy water after each use; then rinse and air or pat dry with clean paper

towels. Cutting boards can be sanitized with a solution of 1 tablespoon of

unscented, liquid chlorine bleach per gallon of water. Flood the surface

with the bleach solution and allow it to stand for several minutes; then

rinse and air or pat dry with clean paper towels. Non-porous acrylic,

plastic, glass, and solid wood boards can be washed in a dishwasher

(laminated boards may crack and split). Even plastic boards wear out over

time. Once cutting boards become excessively worn or develop hard-to-clean

grooves, replace them.

Keep raw meat, poultry, fish, and their juices away from other food. After

cutting raw meats, wash hands, cutting board, knife, and countertops with

hot, soapy water. Be Smart. Keep Foods Apart. Don't Cross-Contaminate Raw or

cooked meat, poultry or egg products, as any perishable foods, must be kept

at a safe temperature during "the big thaw." They are safe indefinitely

while frozen. However, as soon as they begin to thaw and become warmer than

40 °F, bacteria that may have been present before freezing can begin to

multiply. Perishable foods should never be thawed on the counter, or in hot

water and must not be left at room temperature for more than two hours. Even

though the center of the package may still be frozen as it thaws on the

counter, the outer layer of the food could be in the "Danger Zone," between

40 and 140 °F — temperatures where bacteria multiply rapidly.

Learn about the safe way to defrost food: in the refrigerator, or, in

cold water.

Refrigerator Thawing

--- When thawing frozen food, it's

best to plan ahead and thaw in the refrigerator where it will remain at a

safe, constant temperature — at 40 °F or below. Planning ahead is the key to

this method because of the lengthy time involved. A large frozen item like a

pork shoulder requires at least a day (24 hours) for every 5 pounds of

weight. Even small amounts of frozen food — such as a pound of ground meat

or boneless chicken breasts — require a full day to thaw.

Cold Water Thawing

---

This method is faster than refrigerator thawing but requires more attention.

The food must be in a leak-proof package or plastic bag. If the bag leaks,

bacteria from the water, air or surrounding environment could be introduced

into the food. Also, the meat tissue may absorb water, resulting in a watery

product.

The bag should be submerged in cold tap water, changing the water every 30

minutes so it continues to thaw. Small packages of meat, poultry or seafood

— about a pound — may thaw in an hour or less. A 3-to 4-pound package may

take 2 to 3 hours.

Record copious

notes of your procedure, changes in formula, cooking method, temperature,

etc.

Before you begin any

sausage making endeavor:

- Educate yourself concerning health

risks, ingredients, limitations, and food technology as they relate to

your use of the formulations (recipes) that appear here as they pertain

to your personal production of the sausages your are making.

- Obtain a notebook

and begin recording everything you do while preparing the recipe:

materials, grinding the meats, mixing the spices, etc. Record times,

temperatures and humidity where appropriate. Don’t rely on mental

notes, jot important information down...it will be valuable for

troubleshooting cases where you are dissatisfied with the product.

- Read the entire

procedure through, making sure you understand all the nuances of

grinding, curing, spicing, etc. and have all the necessary materials at

hand.

- Assemble and

scrupulously clean all equipment you will be using. (don’t rely on

the cleanliness of stored equipment and utensils.)

- Use latex gloves

when handling meats and mixing in cures and spices.

- Keep all

perishables refrigerated whenever possible through out the procedure.

- Follow the meat

preparation, curing spicing, cooking and/or drying times and

temperatures precisely. Don’t make substitutions unless you completely

understand the effects of the substitution...for example, saltpeter is

NOT a substitute for cure #1 or Cure #2.

Meats used in Sausage Making

A number of different kinds of

meat are suitable for sausage. But the most common are the United States are

pork, beef and poultry. Mutton and lamb may also be used.

Hunters will often include game meats in their sausages, like venison, elk,

antelope, duck, goose and pheasant. My suggestion for game meats, however,

would be to substitute pork fat for the “wild” fat, where dietary and

religious regulations permit. Fat is necessary for both taste and

texture in sausage; if you want to leave out the fat, forget making sausage

and make a meat loaf and substitute bread for the fat! How much fat? That

varies, some sausages are made with a total fat content of 20%; others up to

50%. If sausage contains more than 50% fat, you must call it

“imitation” sausage.

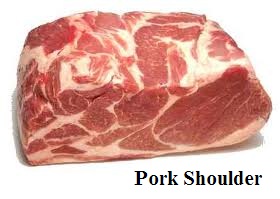

The shoulder is a good and

economical choice for both pork and beef sausages; Pork shoulder is often

marketed commercially as “Boston Butt or Pork Shoulder Butt”, while beef

shoulder is called “Chuck”. The desirable fat to use in sausages is

the hard fat that comes from above the shoulder, that over the loin (back

fat) or the belly around the ribs (bacon). Today's primal cut pork shoulders

contain about 20% fat!

Prepare the meats for sausage by

removing any bones. Next, look for and remove any glandular

meat between the muscle bundles—it will have a quite different

texture and color than the muscle meat and give a bitter taste to your

sausage. Trim away all silver skin (connective tissues: tough, thin shiny

sheets) and any tendons (tough, dense white fibrous sheets). Remove any

visible blood vessels, also. Save any small pieces of edible meat and

fat from this trimming, but don’t mix it in with the “regular” meat you just

trimmed….grind it separately. The picture on the right shows me boning out a

pork shoulder butt.

The picture on the left shows

Glenn, my “sausage-making buddy”, grinding up some pork shoulder. Once you

start making and sharing sausages, you'll find that there are other people

who make sausages or want to learn. Although sausage making can be an

individual thing, its much more fun when you have a buddy who also loves

sausages! You'll practice with spicing and types of meats, the size of

grind, etc. You may make a formula that would be a sure winner in a

sausage-making contest!

We buy the pork in vacuum sealed

bags...they come two “butts” to the bag and weigh in at a total of about

15-18 pounds (or 7-8 kilograms) Some of you will be lucky enough to

raise your own pork, I’m jealous!

In my recipes, I often use the

terms 95/5, 80/20 and 50/50. The first number refers to the lean

portion of the meat and the second number refers to the fat portion. Back

fat is 100% fat!

Types of

Sausage:

FRESH SAUSAGE: I think of

fresh sausage as a sort of "meatloaf" in a casing.

Anyone that can make a “meat-loaf” can make fresh sausage!

My definition of a fresh

sausage is one in which NO curing is required in making the sausage.

Fresh sausage is made of raw meat, salt, and seasonings and

always is cooked before eating.

The amount of salt present in fresh sausage formulations is not necessarily

sufficient to cure the meat. Because the meat is not cured, it must be kept

under refrigeration. They usually take the form of links or patties. Fresh

sausages are very perishable and should be used within several days of their

being made...or else they should be frozen. In my opinion, the beginning

home sausage maker should gain extensive experience with making fresh

sausage, before attempting to make cured sausage. They are not difficult to make. There are a few simple procedures

to follow and precautions to observe, however.

A very

simple general formulation for any fresh sausage is:

|

Meat |

= 80% |

|

Fat |

= 20% |

|

Water |

= 2.5% |

|

Salt |

= 1.5% |

|

Flavorings |

= 0.75% |

|

It is helpful to write your formulations as percentages

because they can easily be converted to weights in the Metric system.

The American and Imperial measurement are difficult to use in the small

quantities used for home sausage formulations. Try this in your head: If you

have 2¼ lb. of meat, how many ounces of salt would you need to yield a 1½%

concentration of salt? Compare that with the ease of using the metric

system. [see below]

As you develop your own particular formula, you will want to

experiment with small batches of sausage. I recommend making one kilogram

batches (1,000g or about 2¼ lb.) This mass will give you enough bulk to

thoroughly mix the ingredients and get an even blend. Taking the above

formula recommendation, multiplying the percentages by a factor of 10 (Yuk —

math!) will give you:

|

Meat = 80% times 10 g Meat = 800 grams

Fat = 20% times 10 g Fat = 200 grams

1000 grams = 1 Kg (about 2.2 lb.)

Salt = 1.5% times 10 g Salt = 15 grams

Flavorings = 1% times 10 g Flavorings= 10 grams

Water = 2.5% times 10 g Water = 25 grams

1050 grams = 1.05 Kg (about 2.3 lb.) |

|

Now you know why your 8th grade teacher stressed

learning multiplication and decimals…wait until we get to biology, chemistry

and physics…and you thought you’d never need to know them!

Let’s examine each ingredient in the general formula of fresh sausage:

Meat: While pork

is the most common meat for sausage making almost any species can be

used. Sausages can made from beef, lamb, domestic and wild poultry, game

meats like deer, elk, antelope, and even fish! In handling home

butchered meats and game you must take precautions to remove all fur or

feathers and keep them from contacting the meat. The animal should be

skinned and the carcass washed to lessen the contamination of bacteria

that can cause food-borne illness, such as E. coli and Salmonella. When

preparing the meat for sausage, trim the meat of all visible fat and cut

it into chunks about 2-inches each. This will facilitate the proper

ratio when building up your formula. [Note: If using store-purchased

meat cuts, avoid buying ground meats. While deep muscle is sterile, the

surface can become contaminated by handling and store grinding. Also

storage greatly increases the chances for bacterial growth. All meat

used for sausage making should be kept under 40oF (4oC).

Remember the phrase “…life begins at 40”.]

Fat: If you

want a low fat product, don’t make sausage! Without 20% or more fat, the

sausage will have a dry, mealy taste and mouth-feel. Sure there are

“fat-replacers” available, but I thought you wanted to make a pure,

healthy product with no extraneous additives! A number of animal fats

can be used. Generally the fat is pork, but beef, lamb, poultry fat and

poultry skin is often used. The one exception is game fat, which

as a very strong wild flavor. The large animal fats can be sorted into

three major categories: sub-cutaneous fat, intra-muscular fat, and organ fat. Sausage makers prefer

to use “fat back”, the hard sub-cutaneous fat under the skin. A good

substitute is uncured and un-salted belly [bacon]. Avoid the soft

and sinewy intra-muscular fat; it produces a poor quality sausage that

contains “stringy” particles that love to lodge between your teeth!

Organ fat, though good quality is almost impossible to get retail.

Prepare that fat as you did the meat, keeping it under 40oF

(4oC); this will insure a good fat definition and avoid

smearing!

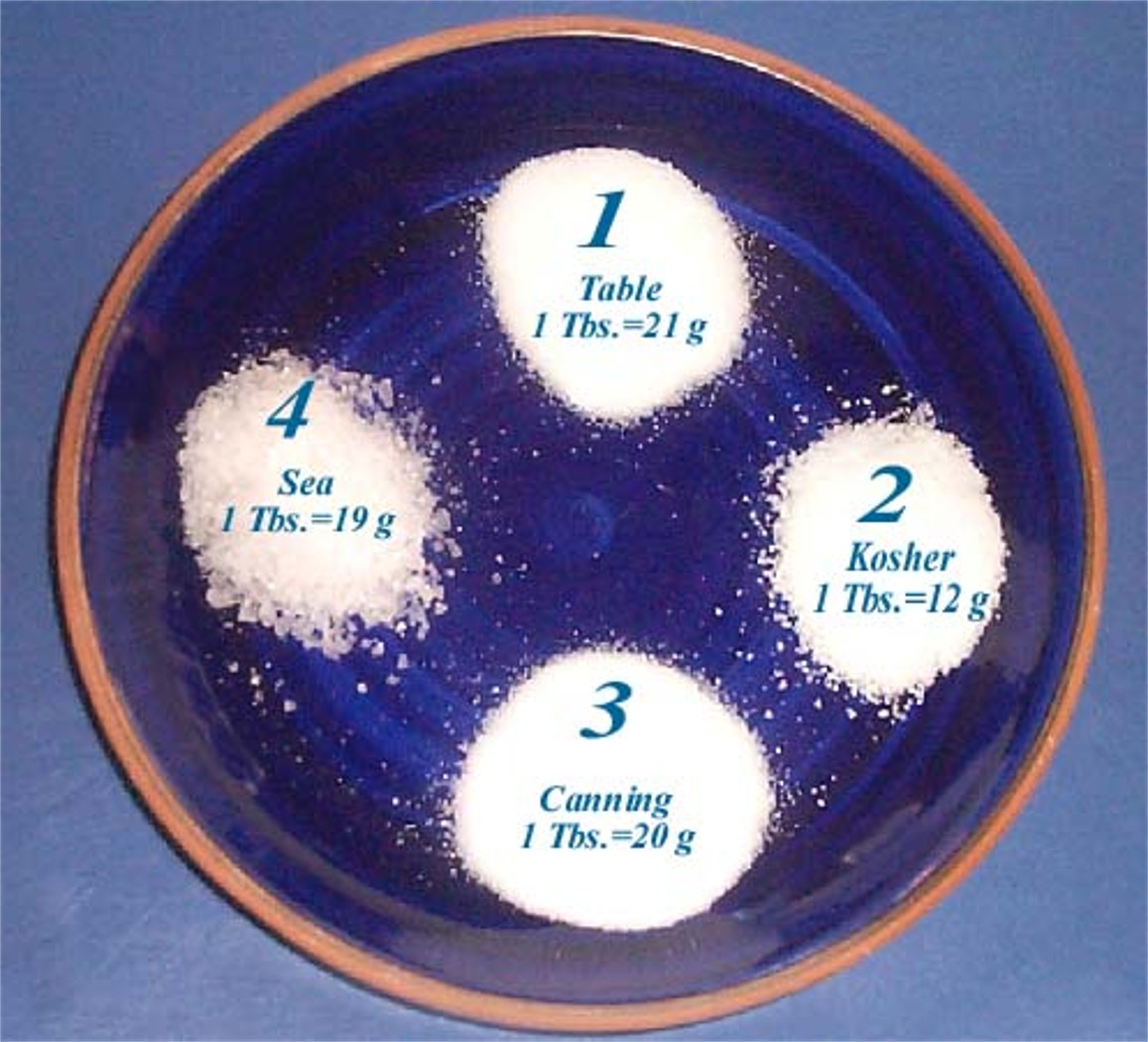

Salt: In

fresh sausage, the percentage of salt is not critical since fresh

sausage is not cured. It’s there for seasoning purposes. I personally

believe than 1½% would be the maximum amount of salt. One thing to

remember is to always weigh the salt. Kosher, pickling, sea and

table salt all have different densities and it is quite easy to over

salt using volume measurements! Note: Some people add a sodium nitrite

curing salt to a fresh sausage to give the meat reddish color. In fresh

sausages this is optional; but nitrite is essential in cooked,

smoked, and dry-cured sausages!

For health reasons, never use more

that 0.25% nitrIte cure in any sausage!

FLAVORINGS:

The most common are pepper, garlic, sugar, chili pepper, parsley, onion,

ginger, coriander, cumin, mace, and sage. But you are only limited by

your imagination. You can use fresh seasonings and spices or dried. If

using dried, remember some are more intense than the fresh variety of

the same seasoning. Toasting dried spices also enhances their flavor.

Alter the kinds and amounts of seasonings to suit your taste, but

beginners remember…too little is better than too much! Keep notes!

WATER:

Water is useful in dissolving the salt and flavoring components so that

they can be distribute evenly through the meat/fat mixture. Make a

slurry of these to add to the meat mixture. As you gain experience, you

might want to substitute wine for water…remember, you are in charge!

PREPARATION OF THE SAUSAGE:

I personally prefer the two stage grinding method. I cut the meat in

chunks large enough to fit in the grinder throat and then grind them

through a coarse plate [3/8-inch or 10-mm]. Next I add the remaining

ingredients to the coarse ground meat and re-grind through a small plate

[1/4-inch or 4.5-mm]. This method produces a sausage mix of equal size

particles and well distributed flavors. This is where you will want to

experiment. Different ratios of meat to fat and different flavorings

will affect the final product. Make accurate measurements and keep

notes and so you can duplicate the formula!

STUFFING:

Stuffing the sausage in a casing is more esthetic than necessary. They

taste the same. True, a sausage is easier to handle, grill, and cook,

etc. when in a link. The most common casings are hog intestines and the

come in a variety of sizes. The suppliers listed on my “Resources”

page have an excellent selection. Generally fresh sausages are twisted

off into 5-inch links; but some prefer the “horseshoe” shaped ring.

STORAGE:

Fresh sausage has a very short shelf-life. It must be kept refrigerated

and used within 5 days. It can be wrapped and frozen for up to a month

or vacuum packed [e.g. Food Saver©] and frozen for about 3 months.

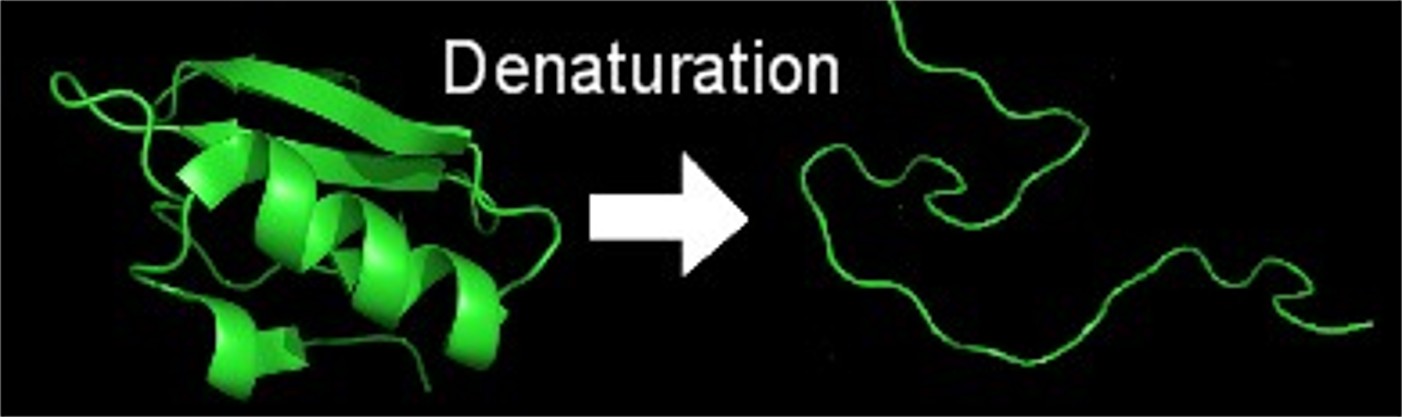

COOKED SAUSAGE:

Cooked sausages require the application of some sort of cure and

heat as part of the formulation and preparation, such as oven-cooking,

poaching, steaming, etc. Cooking causes the denaturation and

coagulation of proteins in the sausage which allows it to maintain its

shape. Smoke may or may not be a necessary part of the preparation.

Generally these sausages may be

eaten without further heating, as in the case of luncheon meats like

bologna, mortadella, and cooked salami. Some like Kielbasa, hotdogs, hot

links, etc. are re-heated before serving. Luncheon meats and hot dogs

are a type of cooked sausage often referred to as emulsion sausages where

the meat paste is so finely chopped that no individual particles of meat can

be seen in the sausage matrix. In order to understand how these sausages are

made, some background information on the nature of meat and proteins is

essential.

What is meat?

Meat is composed of fat, nerve,

tendon, ligaments, sinew and muscle fibers. The muscle fibers, in turn

contain proteins some which are soluble and some that are not. The major

components of muscle protein are actinomyosin and myoglobin (myoglobin is

the red pigment in meat and actinomyosin composes the contractile fibers of

the meat).

Proteins are made up of long

chains of smaller molecules called amino acids. Folds in the amino acid

chain produce the shape of the protein and it’s that specific shape that

determines the protein’s chemical and biological properties. In living

tissue, the function of a protein is dependent on this three-dimensional

structure. Changes in the protein’s environment will disrupt this structure

causing the protein to become “denatured”. This causes the complex folds and

twists in the 3-D structure to break and become linear. These changes can

affect their affinity for water and their solubility. Such environmental

changes can cause by:

-

changes in salt concentration

alters interactions between amino acids that compose

the protein

-

changes in

pH alters interactions between amino acids that compose

the protein

-

breaking the Sulfur-to-Sulfur

bonds that cross-link the amino acids

-

changes in temperature

-

water binding properties.

EMULSIONS:

An sausage emulsion results

is a homogeneous mechanical mixture that results from

meat that is ground so finely

that it encapsulates the fat. These encapsulated droplets are then dispersed

in liquid, in sausage this is generally ice water

Emulsion formation: During the

formation of a meat emulsion, meat proteins are extracted from the meat

muscle and are solubilized [or dissolved] in water. Once the protein is

dissolved additional mixing forces the dissolved proteins to disperse

around and coat fat particles that are present in the meat solution.

An invaluable aid in extracting soluble proteins is salt. The muscle

fibers of the meat contain salt-soluble and heat coagulable proteins,

abbreviated SSHCP. [Note: the amount of water added usually varies with

the formulation from 10% to 35%.]

The extraction of SSHCP is

enhanced by the addition of “sausage-makers” phosphate (e.g. Tri- and

tetra-sodium pyrophosphates). Research has shown that the phosphates

increase protein solubility by altering the pH and salt has a positive

effect on the water-holding capacity of the emulsion by solubilizing the

actinomyosin into actin and myosin. Without added phosphates, long

processing times would result in an unstable emulsion. The Food Safety and

Inspection Service allows for the addition of a 1% solution of sodium

phosphates.

As the protein solubilizes it

coats the fat globules and water droplets in meat paste by wrapping them

in a protein envelope. These globules are evenly dispersed and during the

cooking process the protein looses is biological structure [this is

termed: “denatures”] and coagulates forming a gel around the protein

coated-fat and water particles. This process stabilizes the matrix of fat

and protein forming an emulsion. The process of emulsion formation occurs

in two phases, described below.

Preparation of the Ingredients:

Hard fat and/or fat trimmings

should be free of any soft tissue or sinew. Chill the fat to 34oF

and cut the fat into chunks that will fit easily in the grinder throat.

Grind the fat through a 6.5-mm or ¼-plate. Make sure that the knife blade

is sharp and firmly against the grinder plate. The cut should appear

“clean” and not smeared! If so, check temperature, product purity, blade

sharpness, etc.

The meat should be at

approximately 34oF. Trim the meat so that it contains no more

than 10% fat. Remove all sinew, ligament and connective tissue to

produce a very high quality product. Cut into chunks as you did with the

fat, but grind the meat separately from the fat, through a 4-mm or fine

plate.

Depending on the product

being produced, additional filler products such as tripe, soy protein,

pre-emulsion, etc. may be added. Check your formulation for proper amounts

and preparation of these items and when they should be added to the

matrix.

Phase I:

Mix the ground meat (not

fat) with the salt, cure, phosphates and cure accelerators [such as GDL,

erythorbate or ascorbate], if any. Also at this time mix in

approximately one-half of the water required in the formulation and

process in a cutter or food processor until the temperature of the chop

reaches 43oF. The amount of time is

dependent on the speed of chop, size of batch, etc. Use an infra-red

thermometer to determine the end point.

Phase II:

Add ground fat, the

seasonings, spices, and remaining ingredients to the batter along with

the remaining water and chop or process until the batch reaches 57oF. 18oC

These steps are important.

The first chopping with water and salts results in the extraction and

solubilization of SSHCP so necessary for forming a stable emulsion. As the

mixing continues in the second chop, the remaining water and flavorings are

absorbed by the meat emulsion, contributing to its taste, moisture and

“mouth-feel”

As in the case of making

fresh sausages it is extremely important to maintain your raw materials at a

temperature of 400F. Failure to do so can encourage the

growth of bacteria that lead to illness or spoilage. It is important to

remember that bacteria grow best between 400F to 1400F. When cooking sausages, make

sure they pass through this range quickly. For safety reasons, I

recommend the use of a nitrite cure in all cooked sausages to help control

spore forming bacteria and provide pleasant color retention of the product.

The cooked sausage must attain a final internal temperature of 155-1600F in order to kill any pathogenic

bacteria.

COOKING METHODS

There are two main cooking

methods employed in sausage making that can easily be used by the hobbyist

sausage maker:

Dry-heat and moist-heat. However nothing is really that

simple. Often both kinds of cooking are used on a particular sausage.

Dry-heating can also include the application of smoke to flavor and color

the sausage.

Generally cooked sausages

are prepared in a “Cook House” or smoker. There are a number commercial

smokers are available to the sausage hobbyist. They can be purchased in many

home-improvement centers, sporting goods catalogs, or barbeque stores.

However a homemade smoker can be easily constructed from an old

refrigerator, freezer or even made of plywood. If you make one out of an old

refrigerator make sure it is lined with metal, not plastic. The basic

construction consists of a metal box, a heat source [such as an electric hot

plate] and a pan for hardwood chips or sawdust. Drill some vents at the top

and bottom for draft controls to allow you to regulate the temperature and

smoke.

When using sawdust or wood

chips as the smoke source spritz them with water and place them in a pan on

the hot plate so that they smolder and produce smoke. If you are smoking in

a barbecue grill or kettle unit, keep the hot coals to one side of the grill

and regulate the heat by adjusting the vents. Sprinkle damp sawdust or wood

chips over the briquettes to produce the smoke. An excellent reference for

constructing smokers is “Meat Smoking and Smokehouse Design” by S.,

A., & R. Marianski [see my resource page].

Dry-heat cooking

involves the application of heat

from an oven or smoker that completely surrounds the sausage. By adjusting

openings (dampers) on the oven, the amount of relative humidity can be

somewhat controlled to a value of 40 to 70% R/H.

When cooking sausages in a

smoker, the temperature range should be between 1700F to 1800F. It is desirable to have a high

degree of humidity in the smoker when cooking sausages. This can be

accomplished by keep a pan of hot water in the smoker during cooking. This

keeps the surface from drying out which allows excess internal moisture to

easily escape. An ideal relative humidity for many types of cooked sausage

is about 45%; others may require as much as 70% humidity. There are a

number of humidity gauges available on the market. You’ll have to

experiment with your particular cooker to see how to maintain these

percentages. Phosphates are often added to formulations of sausages to be

cooked by the dry-heat method in order to prevent and excessive lose of

moisture that would produce a dry, mealy product.

Moist Heat Cooking:

This method uses hot water or, in

the case of commercial producers, steam. If product is being cooked in

water, the water temperature should be in the range of 160-1700F. In this case the Sausage is

immersed in hot water which completely surrounds the sausage or loaf to

assure even cooking. Obviously it’s necessary to stuff the sausages in

water-proof casings or in the case of some loaves, a mold with a

water-tight, pressure lid. They should pass from 400F to 1600F as quickly as possible to

minimized bacterial growth. The following internal temperature

combinations are the minimum required holding times to insure that

pathogenic bacteria are killed: 1450F for 10 minutes then raise to 1500F for at least 3 minutes and

finally 1550F for at least 1 minute. Another

reason is to quickly heat and coagulate the proteins and to prevent

rupturing the casing. If higher temperatures are used there is a danger of

driving off water to quickly or melting the fat which results in an

increase in internal pressure causing the casing to burst.

Cooling:

Regardless of the method of

cooking, sausages must be adequately cooled after cooking. The high heat

used in cooking will destroy all actively growing bacterial cells, BUT a

few disease causing bacteria can form spores (think “seeds”) which will

not be destroyed in the cooking process. If the sausage is allowed to cool

slowly, there is a possibility that some of these spores will develop into

active living and growing bacteria! Plunge the sausage in ice cold water

to rapidly cool the meat to about 1000F.

Once cooled, these sausages must be kept under

refrigeration because they are perishable.

Generalized Cooked Sausage Formulation:

Cooked sausages can be made in the form of

links, rings, rolls, or loaves. A general formulation for a cooked sausage is very similar

to that of a fresh sausage, but with some important additions. The most

important difference is that ingredients include nitrite cure and often some

sort of binding agent [Some examples are phosphates, non-fat dry milk, and

soy protein].

|

Meat |

= |

70 to 80% |

|

Fat |

= |

20 to 30% |

|

Water |

= |

1.0% to 10% |

|

Salt |

= |

1.5% to 2% |

|

Flavorings

|

= |

0.75% to 2% |

|

Nitrite |

= |

156 PPM |

Let’s examine each ingredient in the general formula for cooked

sausages.

Meat:

What was said for fresh

sausages can be applied to cooked sausages. In addition to pork, other

common meats are beef, game and poultry. Meat should be treated the same

way:

Trim the meat of all

visible fat, sinew, blood vessels, glands and connective tissue and cut

it into chunks about 2-inches each. The meat used should be chilled 400F (40C)

during the preparation steps. The percentage of meat depends on the

specific formula; often several meats are combined [for example, some

bologna contains a mixture beef, pork and veal]

Fat:

As in fresh sausage,

fat is important for producing a succulent sausage. A variety of animal

fats can be used. Generally the fat is pork, but beef, lamb, poultry fat

and poultry skin is often used. Prepare that fat as you did the meat,

keeping it under 400F (40C); this will insure a good

fat definition and avoid smearing the fat when you stuff the casings!

The percentage of fat varies depending on the type of sausage being

made. Generally when using pork shoulder, you can assume that they have

about 20% fat; Pork bellies about 50%; pork jowls about 70%. You may

have to add fat or meat to obtain the proper percentage for your

particular formulation.

Water:

As in the formulation of fresh sausages, water is used to dissolve the

soluble ingredients so that they can be distributed evenly through the

meat/fat mixture. If the sausage recipe calls for holding the sausage

mixture under refrigeration before cooking, the water/salt/cure mixture

also functions to solubilize the proteins so that the proteins coagulate

and firm up the sausage during cooking.

Salt: The percentage of salt is more critical in cooked

sausage. Besides seasoning the meat, salt is necessary to extract the SSHCP proteins [salt-soluble, heat coagulable proteins] in the meat

muscle. Remember never measure salt as a volume measurement

[tablespoons, etc] but always weigh the salt. Remember

that Kosher, pickling, sea and table salt all have different densities

and it is quite easy to over salt using volume measurements!

Nitrite Cure: In my opinion, nitrite is

essential in cooked, smoked, and dry-cured sausages! The amount of

curing salt is strictly defined by the USDA.

For health reasons, never use more

that 0.25% nitrate cure in any sausage! There are a number of

cures on the market and confusion is often the order of the day. Cure #1

is a cure that contains salt and 6.25% Sodium nitrite [along with a

little pink die and anti-caking agent] --- so read the label carefully!

Flavorings: What was true for fresh sausage, the most common are

pepper, garlic, sugar, chili pepper, parsley, onion, ginger, coriander,

cumin, mace, and sage. You can use fresh seasonings and spices or dried.

Alter the kinds and amounts of seasonings to suit your taste. [Note:

some formulations also call for the addition of skim milk powder, soy

powder, etc. These are generally added to help retain moisture and bind

the ingredients to form a firm sausage. Often these can be omitted

if you prefer not to consume them, but trial and error is needed with

this approach, so make small test batches at first and keep notes!]

Preparation of the sausage: Sausages to be cooked are

generally refrigerated for 24 hours before cooking. The purpose here is

two-fold: it allows the meat to salt cure (solubilizes the SSHCP) and

the flavors to equalize through the meat paste. Use the two-stage

grinding method when preparing cooked sausages. First grind the meat

coarsely through a large grinder plate; then add remaining ingredients

to the ground meat according to the formulation, and re-grind through a

finer plate.

Stuffing: Stuffing is a straight

forward process. The object is to get the meat paste into a form

that can be easily manipulated. The casings used can be natural

intestine casings or artificial casings. Often it is the

preference of the consumer unless you are trying to duplicate the look

of a traditional sausage. The important thing to remember is to stuff

them firmly but not tightly and to use a pin to prick any air pockets

under the casing. Large, heavy sausages will require you to tie them in

links or rings with twine to support them during the cooking process.

Storage:

Cooked sausages have a longer

shelf-life than fresh sausages. The still must be kept refrigerated but

will remain edible after several weeks if properly packaged. They can be

wrapped and frozen for up to a 3 months or vacuum packed [e.g. Food

Saver©] and frozen for about 6

months.

SMOKED SAUSAGE:

Cooked sausages are often smoked in order to enhance their flavor and color

as well as helping to extending the shelf-life of the sausage. It is

important to understand that such smoking does not completely preserve the

sausage unless it was somewhat dried [more about this later]. In general,

sausages to be smoked are air-dried at an ambient temperature of

approximately 680F and

a relative humidity of approximately 60-65% to allow surface water on the

casing to evaporate. Be careful not to over-dry the casing or the smoke will

not penetrate at all. Smoking can be done by either the hot or the

cold method.

Sausage

makers use the

hot-smoke

method for sausage

that is to be partially or completely cooked in the smoker. After drying the

outer casing, smoke is generated while the sausage is cooking. The casing

should be dry to the touch or the “bitter” elements that compose wood smoke

will be deposited on the sausage giving it an off taste. For good smoke

penetration into the sausage, it is important to have a relative humidity of

about 45%. Color development of a smoked sausage is proportional to increase

in temperature -- i.e., the more rapidly the temperature increases, the

faster the color of the sausage will develop. This is the reason why many

formulations suggest a temperature-holding schedule. Sausage

makers use the

hot-smoke

method for sausage

that is to be partially or completely cooked in the smoker. After drying the

outer casing, smoke is generated while the sausage is cooking. The casing

should be dry to the touch or the “bitter” elements that compose wood smoke

will be deposited on the sausage giving it an off taste. For good smoke

penetration into the sausage, it is important to have a relative humidity of

about 45%. Color development of a smoked sausage is proportional to increase

in temperature -- i.e., the more rapidly the temperature increases, the

faster the color of the sausage will develop. This is the reason why many

formulations suggest a temperature-holding schedule.

The cold smoking

method is generally

used to impart a rich smoky flavor without cooking the sausage. Often cold

smoking is used as a drying method for sausages, meats and fish. In addition

to drying the product, the smoke adds color and flavor to the sausage.

Products like mettwurst, teewurst, liverwurst, bacon are often cold smoked.

Temperature is a critical component of cold-smoking. Try to keep the

temperature range between 95-1100F. Depending on which product is

being produced, schedules vary from a few hours to many days in order to get

the proper flavor, color and dryness.

A simple set-up that I use is disconnect

the hot smoking unit from my Bradley smoker. Then I put a 110 VAC hot

plate on a rack in my bullet-type smoker. I replace the bullet top with a

piece of aluminum roof flashing with a 4-inch opening. Then I connect

one end of an 6-foot section (it can be longer) of 4-inch aluminum

dryer-ducting the flashing and the other to a 4-inch opening in my Bradley

smoker. All that's needed now is a small cast iron pan on top of the

hot-plate and a good source of smoking wood. I've tried hardwood

sawdust, but in this set-up I prefer hardwood chunks.

A possible

alternative to smoking in an oven is the use of

liquid smoke.

For example to produce a smoke flavor in sausage loaves cooked in molds,

liquid smoke is added to the water in the formulation at a rate ½ teaspoon/

pound [or more accurately 5.4 ml/kilogram] of meat paste.

Not

long ago a came across another neat way to make a cold smoker from a

galvanized garbage can. The web site is called "Started Smoking...Meat"

at

Mamaliga.com

. Check it out. Another one along similar lines was built from parts

totaling about $50. Check out

Craftbox. No

need to sped a lot to get excellent cold smoked sausage, meats, fish and cheese. The picture of mine, using a Bradley Smoker, will do both hot and cold

smoking depending on how I set it up. Currently the smoking craze has

generated a number of quality commercially available smokers in varying

price ranges.

The Meaning of pH

Before we continue with the discussion of fermented sausage

(below), it's necessary to have an operational definition of pH.

Acids in water

separate into ions (Atoms with electron imbalances are called ions), and the

positive ion is hydrogen (H+). When hydrochloric acid (HCl) mixes with

water, it separates into positive hydrogen (H+) and negative chlorine (Cl-).

Hydrogen (H+) combines with water (H2O) to make hydronium (H3O+). Bases in water also separate

into ions, and the negative ion is hydroxide (OH-). When the base sodium

hydroxide (NaOH) mixes with water, it separates into positive sodium (Na+)

and negative hydroxide (OH-).

The pH-value indicates the degree of acidity

in the meat. Acids all produce Hydrogen ions (H+). Acids like Hydrochloric

acid (HCl) produce lots of Hydrogen ions. Chemists write "hydrogen ion

concentration" as [H+]. The pH of a solution is expressed mathematically as

the negative logarithm of the hydrogen ion [H+] concentration.

When

producing meat products, the pH-value should lie between 4 to 7; pH- values

from 0 to 7 denotes an acidic nature (the smaller the number the more acidic

the solution). The neutral point is 7; pH values from 7 to 14 signify

alkalinity (the larger the number the more alkaline the solution).

When

Hydrogen Chloride gas dissolves in water it form Hydrochloric acid and the

molecules of Hydrogen Chloride dissociate into Hydrogen ions and Chloride

ions.

Water also

dissociates to produce ions, this time it is Hydrogen ions and Hydroxyl

ions.

Sodium

Hydroxide also dissociates to produce ions when it is dissolved in water,

this time it is Sodium ions and Hydroxyl ions.

In each

case we can measure or calculate the concentration of Hydrogen ions present.

In

HCl(aq) Hydrochloric acid

[H+]

= 0.01

In

H2O(l) water

[H+]

= 0.0000001

In

NaOH(aq) Sodium Hydroxide solution

[H+]

= 0.00000000000001

As you can

see, these numbers are small and difficult to read and write. By counting

the decimal places each of the above can be written as:

HCl

(aq)

pH

2

H2O (l)

pH

7

NaOH (aq)

pH

14

Although a pH value has no unit, it

is not an arbitrary scale; the number arises from a definition based on the activity of

hydrogen ions in the solution. The

definition of pH is the number equal to the negative logarithm to base 10 of

the hydrogen ion concentration: This can be represented by the mathematical

formula:

pH = -log10[H+]

Log10 denotes the

base 10 logarithm, and pH defines a logarithmic scale of acidity. A lower pH

value (for example pH 3) indicates increasing strength of acidity, and

a higher pH value (for example pH 11) indicates increasing strength of

alkalinity. Some common pH values found in raw meats used for sausage making

and meat production are:

|

pH 5.8 to

6.2 Pork muscle

pH 5.5 to

5.8 Beef muscle

pH 6.0

Veal

pH 6.5 - 6.7

Chicken

|

Meat with

a low pH-value (pH-value

below 5.8)

has a poor

water binding capacity. This means high cooking losses, inconsistent weight

and a dry, straw-like consistency. For this reason water-bonding chemicals,

like sodium polyphosphates, are generally added to the formulation. It's use

is optional, however. Other additives contribute to good curing features,

such as accelerators like ascorbate or erythorbate, that are used for good

color development and color stability. These accelerators act as reducing

agents and/or lower the pH to provide the environment required to enhance

the rate of conversion of nitrite to nitric oxide, which reacts with

myoglobin plus heat to yield pink-colored nitrosyl-hemochrome [or

nitroso-myoglobin]. The reduction of microorganism growth by the addition of

nitrite results in a longer shelf-life and a longer storability of the meat

and meat products.

For a more scholarly discussion of pH see:

How to

Determine pH or

The

Wikipedia Definition

FERMENTED SAUSAGE

This area of sausage making

is definitely the most complicated and should never be attempted by

anyone who does not have a good understanding of the chemistry and

microbiology involved in the process. The etiology of the word “botulism”,

which is caused by a toxin produced by Clostridium botulinum,

is derived from the Latin word botulus, meaning "sausage"! Inadequate

understanding of the complexity and condition necessary can result in

serious illness or death! In the past history of

fermented sausage-making the procedures were dependent on the art of sausage

maker that was passed down from father to son. Today’s production relies on

our scientific understanding of the fermentation process and microbial

action to produce a high quality safe product that minimizes or eliminates

pathogenic and spoilage bacteria.

Sausages that are produced

as a result of bacterial fermentation are classed as either dry or semi-dry

sausages. The fermentation results from the ‘digestion” of carbohydrates in

the meat paste resulting in an accumulation of lactic acid. As a result, the

pH is generally reduced to pH 5 or lower. Fermentation is ancient

process of preserving meats. In the not too distant past, chopped meat was

mixed with salt and allowed to “sour”, producing an edible sausage. The

technique was very unreliable since it depended on the presence of “good”

bacteria in the meat mixture—which was not always the case.

A modern and more

scientific approach is to create a mixture of salt, sodium nitrite and

sodium nitrate, and a "starter" culture of acid-producing bacteria [LAB -

lactic acid bacteria], which is mixed with ground meat. Using the more

modern method, pathogenic bacteria die or are inhibited by the amount of

acid produced during fermentation and the lack of moisture in the finished

product. Among other things, the nitrite/nitrate salts control the

development of botulinum spores produced by Clostridium botulinum.

With respect to

the pathogenic bacteria Salmonella, Listeria, and

Staphylococcus aureus, the first hours and days of fermentation are

critical. The rapid development of LAB competing with the spoilage bacteria

is very important because the produce an environment conducive to a rapid

reduction in the pH to below 5.4. The growth and development of desirable

LAB is favored by curing salt, anaerobic conditions, added sugars, and

a low initial pH of the meat paste. With regards to

Escherichia coli serotype O157:H7 the

jury is still out. E. coli has been reported to survive in the

fermentation environment of salami in commercial production in California,

Washington and Australia in the '90's causing a number of people to become

ill. It was estimated that fewer than 50 organisms may have been

present in the dry fermented salami which caused infection in the Washington

State outbreak, so it is important to be able to predict the efficacy of

production practices. A 1997 CDC report indicated 61 deaths due to

Escherichia coli O157:H7. The FSIS

requires what is termed a 5-log reduction in the pertinent

pathogenic microorganisms (i.e., reduce pathogens by 100,000-fold ) or

a hold until tested before release procedure.

Since the 90's, FSIS regulations, industry cooperation and testing have

minimized the danger of E. coli contamination. It is extremely

important that home-sausage makers be exceptional careful and clean when

preparing dry-cured products; always grind your own meat from large muscle

-- never use pre-ground meats from a butcher shop or supermarket because of

the possibility that the meat may have been in the case long enough for

bacteria to multiply to a dangerous level!

Dry sausages, like salami, are not cooked but are hung to dry

after fermentation until there is a 25% or more loss [by weight] in

moisture. The drying period depends upon a number of conditions: choice of

meat, the formulation and method of fermentation, the diameter of the

casing, temperature and humidity of the drying room, etc. A dry cured

sausage with a diameter larger than 1¾-inches is commonly referred to as

“salami”. The overall maturation may require anywhere between 30 and 90

days. The resulting sausages are “raw” but shelf-stable and can be kept

without refrigeration for several months. Sausage fermented with bacteria

and a nitrite/nitrate cure is not “cooked” as we understand the term. There

is more information about this process later in the section on “Making

Salami”.

Semi-dry sausages are a variety of sausage that is

harder and denser than fresh sausage, but not as hard as a dry sausage. They

are generally smoked, cooked or a combination of both processes. Then they

are air-cooled and dried until about 10-15% of their moisture is lost.

Although somewhat dried, they are not shelf-stable unless refrigerated.

Since they are fully cooked or fermented, they can be used as a ready-to-eat

sausage. Summer sausage, Lebanon bologna and smoked beef stick are a good

example.

A general formula

for a dried or semi-dried sausage is:

|

Meat, lean |

= 72% |

|

Fat, hard |

= 25% |

|

Salt |

= 2.5% |

|

Carbohydrate |

= <1% |

|

Seasonings |

= 1% |

|

Starter Culture |

= 0.1% |

|

Nitrite |

= 156 PPM |

General Ingredients used

in Fermented Sausage.

Meat: The meat is generally

moderately chopped, although in some specialty sausages, like German

Teewurst, are finely chopped. Many of the varieties of fermented sausages,

like summer sausages, are cold smoked. Use only the highest quality of

meat when making fermented sausage. A number of meats work well. Generally

there is a high percentage of pork and beef in most fermented sausages.

The reasons are quite technical and have to do with muscle chemistry and

denaturation. The beef/pork mixture improves the color of the final

product, allows for better protein solubilization, and improves drying

rate. A typical proportion is 55% lean pork and 15% lean beef. [Many

commercial makers prefer older animals like bull meat to beef]. In

the US the next most utilized meat is poultry meat and, to a much lesser

extent, veal and lamb.

Fat: One must be more careful in the

selection of fat that is used for these kinds of sausages. The best fat to

use is pork back fat which has a high melting point. Lower quality fats,

like intramuscular fats [often termed “soft-fat”], generally have a

greater tendency to oxidation that produces off-flavors and contributes to

rancidity. Note: Long cold storage of fat is not recommended because the

enzymes that breakdown fats into fatty acids are not inhibited by cold

temperatures – do not store frozen fat more that than 60 days.

Curing Salts: The essential

ingredients are salt (NaCl), sodium nitrite (NaNO2) and sodium nitrate (NaNO3). The salt concentration is

usually recommended to be 2½%-3%; the maximum concentration of nitrite

is ¼-ounce per 100 pounds of meat. The salt solubilizes the protein so

the other reactions necessary for fermentation can take place. Nitrate

is added to fermented sausages because the long aging process uses up

most of the nitrite and bacteria present in the meat paste slowly

convert the nitrate to nitrite. By the completion of fermentation and

dry-aging the majority of the nitrite is “used up” and converted to

gaseous nitric oxide. This gas combines with myoglobin producing the

pink color of the sausage. The action of these chemicals are necessary

for the solubilization of protein and inhibiting the growth of most

micro-organisms while providing a suitable environ for lactic acid

bacteria to thrive.

NaNO3 →

NaNO2 → Na + NO + Myoglobin → Nitroso-myoglobin

(pink color)

You will notice that

some formulations for fermented sausages call for the addition of citric

acid, sodium erythrobate or ascorbic acid. These compounds, called

anti-oxidants, are added to inhibit the formation of cancer-causing

nitrosamines as well as stabilize color and prevent oxidation of fat

that would produce off-flavors.

NITRITE USED IN CURED, COMMINUTED

PRODUCTS

Excerpted from PROCESSING

INSPECTORS' CALCULATIONS HANDBOOK,

Revised 1995,

Food Safety

Inspection Service, USDA

The amount

of ingoing nitrite permitted in comminuted products, such as bologna,

specific and nonspecific loaves, salami, etc., is based on the green

weight of the meat and/or poultry and/or meat/poultry byproducts (meat

block) used in the product formulation. Shrinkage is not a factor in the

calculation. If nitrate is used in conjunction with nitrite, the limits of

the two compounds are calculated separately and the permitted maximum of

each may be used.

Calculation Formula

PPM =

(pounds of nitrite x 1,000,000) ÷ green weight of

meat block

* Green Weight - The weight of the meat and/or poultry

(ham, breast, belly, beef or pork trim for sausage, etc.) prior to

processing (grinding, pumping, breading, cooking, drying, etc.). Nothing

has been added or removed from the meat and/or poultry.

MAXIMUM INGOING NITRITE AND

NITRATE LIMITS (IN PPM)

FOR MEAT AND POULTRY PRODUCTS*

Curing Agent

Curing Method

Immersion Cured

Massaged/Pumped*

Comminuted** Dry Cured***

Sodium Nitrite

200

200

156 625

Potassium Nitrite

200

200

156

625

Sodium Nitrate

700

700

1718 2187

Potassium Nitrate

700

700

1718

2187

* There are

more stringent limits for curing agents in bacon to

reduce the formation of nitrosamines. For this same

reason, nitrate is no longer permitted in any bacon

(pumped and/or massaged, dry cured, or immersion cured).

**Cured,

Comminuted Products - Products consisting of coarsely or

finely ground meat and/or poultry and cure ingredients

mixed together (bologna, turkey salami, pepperoni,

pepper loaf, etc.).

***Cured,

Dry Products - Products that have dry or powdered cure

ingredients directly applied to the surface of the meat

or poultry muscle (ham, pork shoulder, pork belly,

etc.).

As a matter of policy, the

FSIS requires a minimum of 120 ppm of ingoing nitrite in all cured "Keep

Refrigerated" products, unless the establishment can demonstrate that

safety is assured by some other preservation process, such as thermal

processing, pH or moisture control. This 120 ppm policy for ingoing

nitrite is based on safety data reviewed when the bacon standard was

developed.

There is no regulatory minimum

ingoing nitrite level for cured products that have been processed to

ensure their shelf stability (such as having undergone a complete thermal

process, or having been subjected to adequate pH controls, and/or moisture

controls in combination with appropriate packaging). However, 40 ppm

nitrite is useful in that it has some preservative effect. This amount has

also been shown to be sufficient for color-fixing purposes and to achieve

the expected cured meat or poultry appearance.

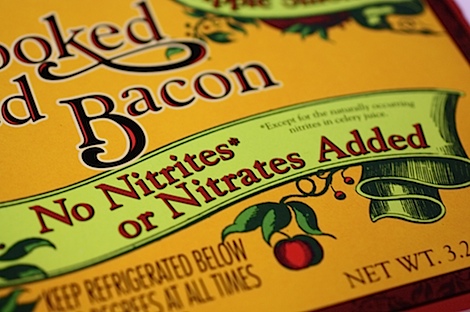

A note on using celery powder to cure

sausage:

|

A confusion exists in some folks that nitrites and nitrates might

cause cancer. The U.S. National Toxicology Program (NTP),

completed a multi-year study in which rats and mice were fed high

levels of sodium nitrite. The study found that nitrite was not

associated with cancer. NTP maintains a list of chemicals found to

be carcinogenic. Sodium nitrite is not on that list.

In order to be considered “cured,” sausage meats must contain a form

of nitrite. Nitrites provide protection against the growth of

botulinum toxin-producing organisms. Sodium nitrite is a safe,

government-approved curing ingredient that gives cured meats their

characteristic taste and color. Its health benefit is that it

prevents the growth of C. botulinum (the cause of botulism). Without

nitrite, cured meats won’t have the taste and appearance that makes

a salami taste and eat like salami. A meat or sausage label that

says “natural, uncured, or no nitrates or nitrites added” simply

means that no commercial sodium nitrate or sodium nitrite chemical

salts were added to cure the meat. However it does not mean that

the product is free of nitrates or nitrites.

Celery or beet powder is often cited as a curing agent and

substitute for chemical nitrite and nitrite salts. Celery powder

contains a significant amount of naturally occurring nitrate.

Celery powder prepared from celery juice has been shown to have a

nitrate content of approximately 2.75%. Unlike standardized curing

salt mixtures, there are no standards of nitrite or nitrate content

in a celery juice powder. A vendor of celery juice powder should

provide you with some sort of certified analysis indicating the

content of nitrite and nitrate in their product. Hopefully they will

provide a suggested usage level for their extract! Otherwise you

will need to calculate how much powder you need to produce 156 ppm

concentration of nitrate to be added to the sausage.

Neither celery powder nor other natural sources of nitrite are

approved for use in 9 CFR 424.21(c) as curing agents for meat. They

are allowed as flavoring agents, however. (“Celery powder can be

added to meat and poultry products as a flavoring in accordance with

317.2(f)(1)(i)(B) and 381.118(c)(2) along with other natural sources

of nitrite such as beet juice and sea salt. Because celery powder

and other natural sources of nitrite are not currently approved for

use in 9 CFR 424.21(c) as curing agents, products that are required

to contain chemical curing agents and cure accelerators as part of a

standard of identity in 9 CFR 319 or 9 CFR 317.17(b) but instead are

formulated with natural sources of nitrite and ascorbate (e.g., hot

dogs and corned beef that contain celery powder instead of sodium or

potassium nitrite and cherry powder instead of ascorbate) must be

labeled as "uncured" under 9 CFR 319.2.”--- Code of Federal

Regulations)

Also see:

Is celery juice a viable alternative to nitrites in cured meats?

|

Using the above

information and formula, what is the PPM of nitrite in a formulation for

Italian salami the uses 6.0 grams of Cure#2 for 2.5 kilograms [or 5.5

pounds] of meat? Converting from the metric to standard American

measurements shows that 6 grams is equal to 0.21164ounces of cure; but

only 6.25% of that weight is nitrite! So the actual amount of nitrite is

equal to 0.01322 ounces [0.21164 ounces x .0625] or 0.0008267

pound of nitrite [0.01322 ounces / 16

ounces/pound]. Substituting in the above formula, we get:

PPM =

(pounds of nitrite x 1,000,000)

÷ green weight of

meat block

PPM =

(0.0008267 x 1,000,000)

÷ 5.5

PPM = 826.7

÷ 5.5

PPM = 150.3

Similar calculations can

be preformed separately for the PPM of nitrate in a formulation,

remembering that cure#2 contains 4% nitrate. Both nitrite and nitrate

are calculated separately.

Note: be careful of formulations posted on the

web, one I saw for Italian salami contained only saltpeter as a cure

(Potassium nitrate) at the rate of 3,547 PPM (only 1718 PPM are

permitted)!!!!

Starter Cultures:

I am often asked questions

that relate to the fact that a person’s family recipe does not include

the use of starters and they have had no problem. All I can say is that

they’ve been lucky. I liken it to turnpike driving; if you do everything

correctly, there is a pretty good chance of not getting killed … but

it’s not a surety! Bacteria can get into the meat mix buy chance

contamination; by an old commercial method called “back slopping” where

a portion of a previous meat mix is added to the newer one; or, by the

addition of a “starter culture” of known bacteria that are generally

regarded by the USDA as safe for human food preparation. Starters have

been used in the beer, wine, cheese and baking industry for many years

and the consistency of their products depend upon them.

The use of starter

cultures has become standard practice in the meat industry because they

provide a safe environment for beneficial bacteria and inhibit spoilage

and pathogenic bacteria. Laboratory experiments have shown a rapid

decline in populations of enterobacteria [like E. coli] in

proportion to the rapid increase of starter culture bacteria [like

Lactobacillus sp. and Pediococcus sp.]. There is an extensive

coverage on the selection and use of starter cultures on this page and

the reader is encouraged to study it carefully before attempting to use

any starter. The bacterial cultures are quite specific with the

manufacturer’s suggestions of optimum growth requirements … always

follow their suggestions!

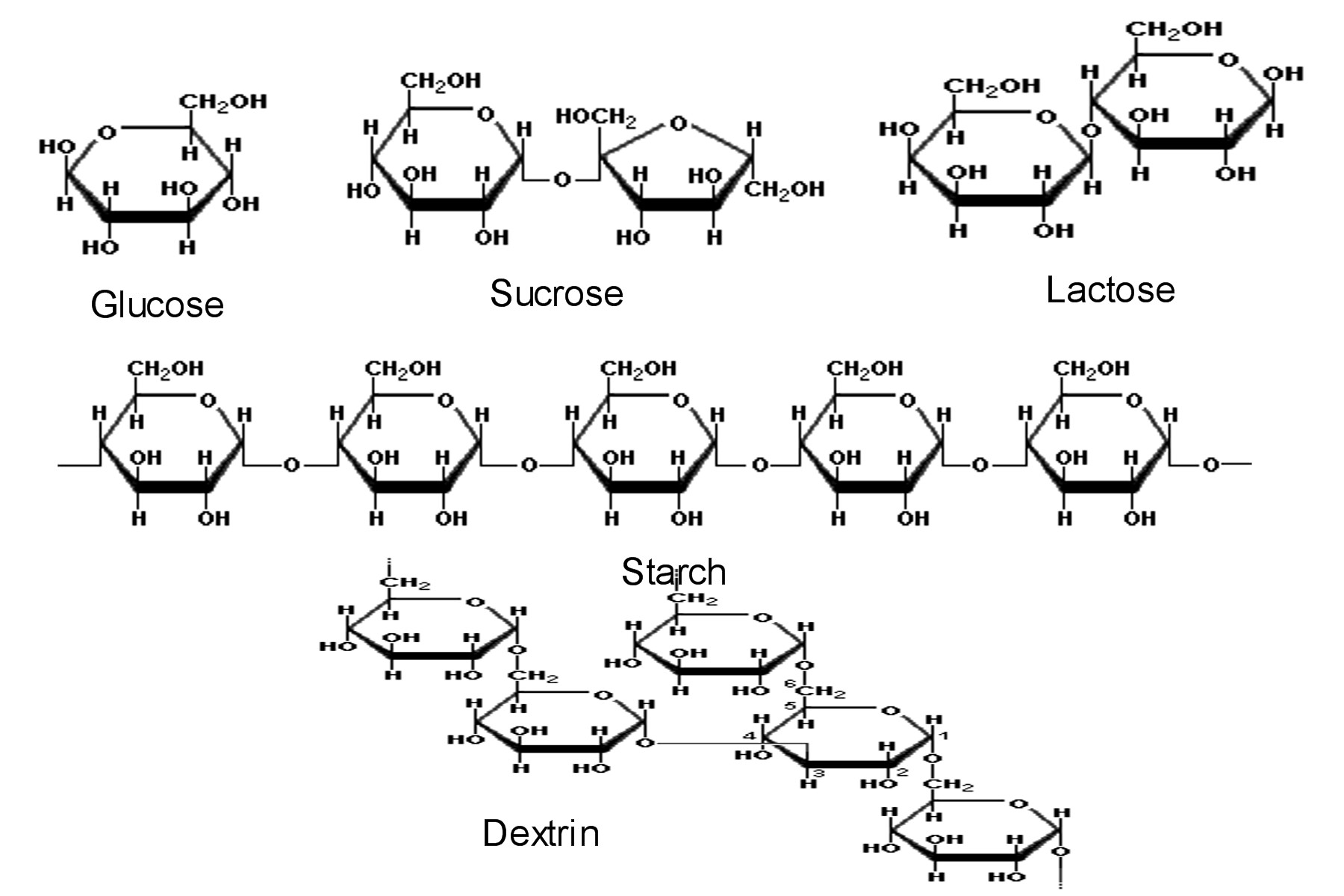

Carbohydrate:

Some

formulations may contain glucose, sucrose, lactose, starches or dextrins.

These carbohydrates are metabolized at different rates thereby

regulating the speed and degree of acid formation in the sausage. The

purpose is to provide fermentable substrate so that the bacteria in the

meat can ferment it and produce lactic acid. The most commonly used

carbohydrate is glucose [also called dextrose] because it is the

simplest in molecular construction and most readily utilized by

bacteria.

Some

formulations also call for the use of some sort of binder to assist in

holding the sausage together and making it firm. These are generally

used in commercial products. They include such things as non-fat dried

milk and corn syrup solids. In home produced products that can be

considered optional and a matter of personal preference of the sausage

maker.

Seasonings:

The purpose of seasonings is

to enhance the flavor of the sausage and often to influence its color.

Common seasonings are various combinations of pepper, garlic, paprika,

spices; for example, mace, thyme, sage coriander oregano mustard seed,

cloves, and anise seeds. Some seasonings like

garlic, pepper and rosemary also have antibacterial properties.

Generally, the spices are used in their dried form, although

commercially extracts and oils are frequently used. With exception of

pepper, garlic and paprika, spices are generally 1% or less of the

formulation. They are the one variable that can be manipulated to suit

the sausage makers’ taste.

Fermentation: The main objective of

fermentation is to achieve the correct temperature for bacterial growth

and development, which in turn will cause rise in acidity [or a drop in

pH]. Complete fermentation will depend upon the bacterial flora present,

temperature of incubation, humidity and diameter of the sausage; this

can take anywhere from 12- 48 hours. The temperature, using starters, is

generally in the range of 85-950F and a relative humidity as

high as 90%. You will notice that as fermentation progresses the sausage

slowly changes from a tan-light brown color to a redder color as the

nitrite is reduced to nitric oxide and myoglobin becomes oxidized. The

soft meat paste of the sausage begins to “firm up” as the lactic acid in

the meat begins to accumulate; you will also notice a strong acidic

aroma.

At this point, the production procedure for

dry and

semi-dry sausages takes a somewhat different path.

After fermentation the semi dry sausage is finished by cooking in a

smoker, at a temperature of approximately 140 – 1550F and a relative humidity of

80% for a period long enough to ensure that all microbiological activity

is halted. The heat and relative humidity are then readjusted to meet a

specific temperature/time requirement, set by the FSIS/USDA, sufficient

to eliminate pathogens. [The smoking period should be for a minimum of 1

hour at 35%R/H at a temperature high enough to produce an internal

temperature of 1400F]. This will produce a sausage with a moisture level of about

50%. Since the moisture level is relatively high, semi-dry sausages must

be refrigerated to prevent spoilage. Always carefully follow the

cooking/smoking schedule in your formulation!

Drying: Drying is a critical stage in

the production of fermented sausages. The main objective here is to

remove water from the sausage. The drying should proceed in an

environment where the relative humidity is approximately 5 to 8 percent

below the moisture in the sausage. If drying is too fast, a hard layer

of protein will form just under the surface forming a waterproof shell

[referred to as “case-hardening”]. This will prevent interior moisture

from diffusing out of the sausage and contribute to possible spoilage.

This dictates that the humidity must be progressively reduced as the

sausage dries. If the sausage is to be

dry cured, then with a humidity

starting in the high 80’s, gradually decrease the relative humidity to

approximately 65% over the span of several weeks of drying. The

total loss in weight of the product (from its wet or “green” stage

should be at least 30%. If the sausage is to be

semi-dry cured, the total loss in weight

should be a minimum of 10%, with 15% being the average. Follow the

directions carefully for your particular formulation. Regardless of the

type produced, the drying area should have a regular exchange of fresh

air; this could be accomplished with a tiny fan. Target the CFM to about

¼-foot/second.

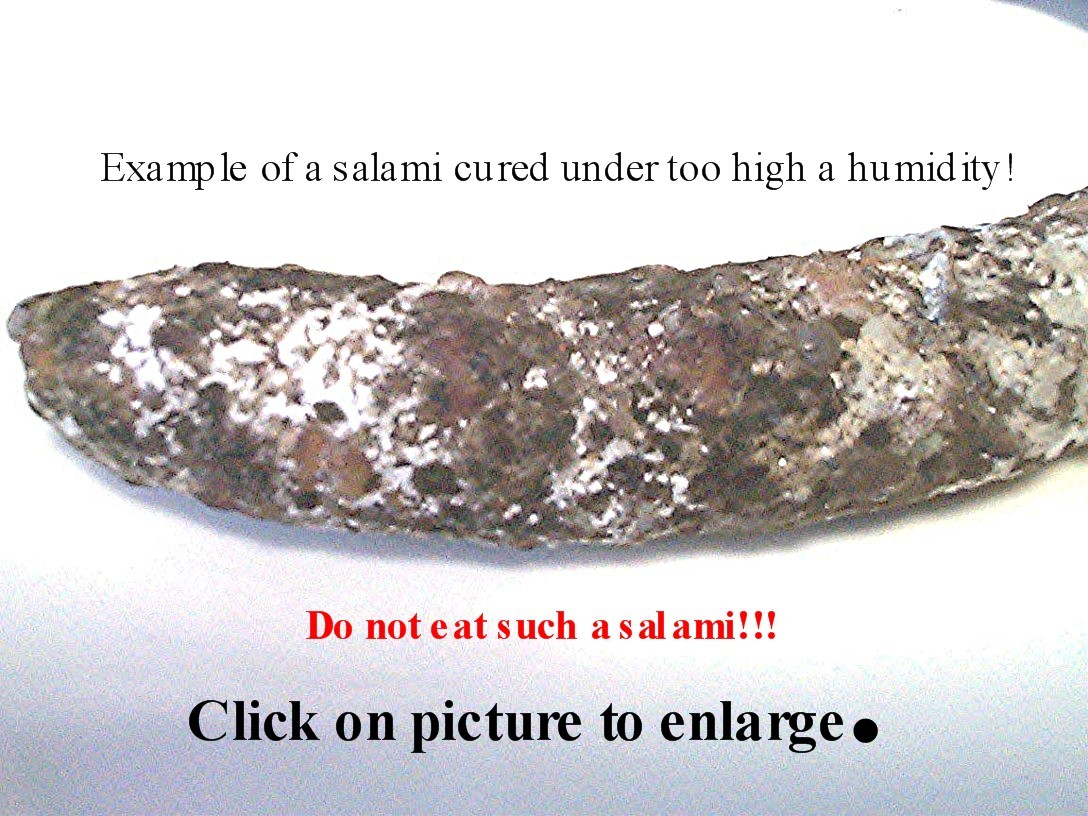

Mold

Development: I often get

questions on mold development on the surface of such products as salami.

You should know that in the more humid environments of Southern Europe, it

is desirable to have sausage dried in an environment that encourages the

development of a “noble” mold .. a species of Penicillium. This

mold is a fine white powdery covering over the surface of the sausage.

(see photo at the right) It develops naturally in those areas since the

mold spores are so common in the air. BUT, there are other mold spores in

the air which are not desirable. These are black, green and brown

molds; some might be reddish and they can be quite fuzzy or wispy. To be

safe, I suggest using a starter mold which is added to the surface of the

sausage before drying takes place. One such mold culture is

Bactoferm M-EK-4, which is a pure culture of Penicillium nalgiovense

manufactured by Chr. Hansen, Co.

The photo below

shows salami at various stages off their aging and maturation. The extreme

left ones are almost ready to be eaten, while the extreme right salami

have just begun the aging process. The growth of filamentous fungi on the

surface of salami during ripening is an important factor for the quality

of the product quality because it helps the biochemical changes involved

in the process of maturation. Some of these fungi, however, can cause

problems related to discoloration and off-flavor, as well as damage on the

casings. In addition, some fungi are associated to health hazards due to

toxin production. .The

growth of desirable molds on the surface of salami enhances the maturation

process in by preventing the development of "case hardening" on the

surface of the sausage. Penicillium mold degrades lactic acid that

is produced throughout maturation, resulting in a slight pH increase and a

decrease in sausage tang. Penicillium nalgiovense is a

species of the genus Penicillium and it is a frequently used

starter culture for mold ripened dry-cured sausages and salami. P.

nalgiovense related very closely to P. chrysogenum, a well

known producer of the antibiotic penicillin.

Similar strains of Penicillium are used in the cheese industry, for

example,

Penicillium camemberti and Penicillium roqueforti, used in the

production of Roquefort and Camembert cheeses.

The surface

growth of P. nalgiovense suppresses the growth of other

undesirable organisms such as indigenous molds, yeasts and bacteria. This

species is indigenous to a number of

areas in Southern Europe and areas in Southern Europe and  the

some areas of the United States, especially the San Francisco Bay Area. In

these areas the mold grows rapidly on salami given the proper temperature

and humidity. Optimum growth conditions are 64oF/18oC and 60% R/H. In the picture on the right, the salami on the right

side of the plate is covered with indigenous (wild) molds, whereas the on

on the left has been inoculated with a Penicillium nalgiovense

starter culture. Notice the more even and full coverage on the

salami inoculated with P. nalgiovense. The growth is so rapid in

this case that other potentially harmful molds are crowded out and

prevented from growing on the casings. In some areas of our country there

are a number of indigenous molds that are strains of P. nalgiovense

that a good coverage of mold is obtained. However, the starter cultures

are relatively inexpensive and last for a long time. If you make salami

often enough, the walls and ceiling of maturation and aging area will

contain many active spores after a period of time and you'll find that

there may be no need to inoculate with fresh starter! the

some areas of the United States, especially the San Francisco Bay Area. In

these areas the mold grows rapidly on salami given the proper temperature

and humidity. Optimum growth conditions are 64oF/18oC and 60% R/H. In the picture on the right, the salami on the right

side of the plate is covered with indigenous (wild) molds, whereas the on

on the left has been inoculated with a Penicillium nalgiovense

starter culture. Notice the more even and full coverage on the

salami inoculated with P. nalgiovense. The growth is so rapid in

this case that other potentially harmful molds are crowded out and

prevented from growing on the casings. In some areas of our country there

are a number of indigenous molds that are strains of P. nalgiovense

that a good coverage of mold is obtained. However, the starter cultures

are relatively inexpensive and last for a long time. If you make salami

often enough, the walls and ceiling of maturation and aging area will

contain many active spores after a period of time and you'll find that

there may be no need to inoculate with fresh starter!

A number of

native or indigenous molds are unsightly; some will impart an "off" flavor

to the salami and yet others might produce toxins that are harmful.

The major problem with taking a chance and hoping

that desirable native molds will grow on the surface of your dry-cured

sausages is that other non-desirable molds may also grow and some may be a

health hazard. This is especially true if the proper humidity is not

maintained. Click on the picture at the left, it shows a number of

indigenous molds that have grown on a salami cured under improper

humidity. Never eat a salami that looks like this. Peeling off the casing

will not remove any of the mold that has penetrated the meat! If you

desire that nice white "bloom" on your salami, I suggest that don't put

your trust in indigenous molds instead purchase a mold

starter culture from a supplier, such as

Butcher and

Packer Company.

DRY-CURED PRODUCTS: Dry-cured meats are those commonly

held without refrigeration; example, Smithfield-type hams and prosciutto

among others. The meats used in these products are generally whole muscle

meat like ham or loin. Dry-cured pork products are often eaten uncooked.

Prescribed concentrations of salt are a necessity for making dry-cured

sausage and meats. A lot of discu ssion can occur around this

topic and the reader is cautioned when searching the WWW that many

opinions are just that..OPINIONS! Always consider the sources! Seek

out official government regulatory sources, research reports and industry

standards before attempting to alter any recipe. ssion can occur around this

topic and the reader is cautioned when searching the WWW that many

opinions are just that..OPINIONS! Always consider the sources! Seek

out official government regulatory sources, research reports and industry

standards before attempting to alter any recipe.

For official guidelines on

curing, you should at least check the following publications: Canadian

Food Inspection Agency - Chapter 4 Annex A: Approved Curing Methods

To Ensure The Destruction Of Trichinella In Sausages And Other Meat

Products Containing Striated Pork Muscle Tissues. CFIA

View Citation.

If you wish to

see an excerpt of the USDA citation, click here —>

Citation.

It is strongly recommended that

before attempting to make any dry-cure product that the reader review the

documents linked above and below that relate to guidelines for the

destruction of Trichinae (causes Trichinosis) in pork

muscle. Trichinosis:

Centers for Disease Control and

Prevention,

Division of Parasitic Diseases

Fact Sheet. (View the document).

Please be advised that the treatments described in those documents are

not designed to destroy pathogenic bacteria that may also be present

in meat. Among those organisms are Clostridium botulinum

(causes Botulism), Escherichia coli O157:H7, Listeria

monocytogenes, and Staphylococcus aureus.

/

The use of salt, time,

temperature and nitrites play important roles in the curing of meat. The

curing and aging processes either kill or minimize these organisms so as

they are not infectious. There are strict guidelines regarding the

processing, curing and aging of meats which are completely described in

both the publications of the Food Safety And Inspection Service of the

United States Department of Agriculture as well as the Canadian Food

Inspection Agency.

The maximum amount of nitrite

applied to the muscle being dry-cured cannot exceed 625 PPM.

To be certain that sausages are

Trichina-worm free, the sausage maker is encouraged to process the

raw pork according to instructions in the above cited documents and

summarized as shown in the table below. This will result in what is termed

"certified pork", an industry term for pork that has been handled

according to USDA requirements. Don't expect to go to your local

supermarket and ask for "certified pork" unless you enjoy seeing blank

stares.

Freezing Requirements for Trichina-free

Pork

Federal Meat Inspection Service - USDA

|

Freezer

Temperature |

Meat Thickness

6 inches Thick or Less |

Meat Thickness

6+ to 27 Inches Thick |

|

5°F (-15°C) |

20 Days |

30 Days |

|

-10° (-23.3°C) |

10 Days |

20 Days |

The use of salt, time,

temperature and nitrites play important roles in the curing of meat. The

curing and aging processes either kill or minimize these organisms so as they are

not infectious. There are strict guidelines regarding the

processing, curing and aging of meats which are completely described in

both the publications of the Food Safety And Inspection Service of the

United States Department of Agriculture as well as the Canadian Food

Inspection Agency.

The maximum amount of

nitrite applied to the muscle being dry-cured cannot exceed 625 PPM or 1

ounce per 100 pounds of meat block..

The curing ingredients

are placed on the surface of the meat and draw moisture away from the

muscle forming a brine. This brine facilitates the movement of salt (and

nitrite/nitrates, if used) into the meat. In some products only salt is

used and the meat is completely packed with a thick covering. The

disadvantage of this procedure is that the meat becomes overly salty and

discolored. This process is rarely used commercially today, but it was

commonly used by homesteads in the past to preserve lard and make salted

pork.

In contemporary times a

modification of salt curing is used. The newer method used sugar, nitrite

and nitrate mixed with the salt to make a “curing salt”. Its is important

to understand that the amount of nitrite used for dry-curing muscle meats

cannot exceed 625 PPM; the amount of nitrate cannot exceed 2187 PPM. It

should be noted that the FSIS/USDA now forbids the use of nitrate in

commercially produced bacon .. only nitrite and ascorbic acid are

permitted in the cure.

A general formula for a

dry-cured product:

|

Muscle meat |

= 20

lb. |

|

Salt

|

= 1.2

lb. |

|

Sugar

|

= 0.5

lb. |

|

Curing

salt |

= 0.2

ounces* |

*based on