|

The Production of Fermented Dry Salami:

Background: Salami production has always been due to the presence and life activities of lactic acid bacteria in the meat and the meat preparation area. In the past, salami making was thought of as an art because sausage makers did not have an understanding of the effect of bacterial growth in the meat paste. Meat was chopped, salt was added along with spices and the salami maker had a protocol to follow that produced an edible product...most of the time! The indigenous bacterial contaminants worked their "magic", but the results were not always successful. If the bacteria activity resulted in a high pH, spoilage bacteria could grow and, in the worse case, pathogenic bacteria had a population explosion in the salami.

With research in the academic institution, bacterial growth and fermentation

processes we elucidated and "starter bacterial cultures" became available

for commercial production which resulted in a uniform and consistent

product. With the introduction of starter cultures, salami production became

less of an art and more of a science. It is now know that a large

family of bacteria, the lactic acid family, is essential for good,

consistent product development. However not all lactic bacteria are

desirable; some prefer to live in an oxygen rich environment, while other

prefer anoxic environments. It seems that this group has very specific

substrates that they rely on for food. Some produce buttermilk from

milk sugars and others produce cheese and others produce yogurt. Some like

certain starches and produce the flavor complexity of sour dough bread,

others like wheat and barley and contribute to the flavor of beer,. A small

group prefer to live in ground meat and convert glucose to lactic acid!

Those are the ones we use to make salami!

The Meat Paste:

Regional traditions dictate the types of meat and fat used in the

manufacture of salami. I prefer to use pork shoulder butts when the recipe

calls for pork, beef chuck when beef is used. For fat, I prefer to use what

is termed pork back fat, which is the fat trimmed of the top of loin area

along the back of the pig; another choice would be "fat bellies", the same

cut of meat used to make bacon. Other choices are pork jowls and beef

cheeks! As mentioned previously the pork meats should be pre-frozen

according to the schedule outlined by the USDA--in the business, this is

referred to "certified pork"--which means that the pork has been certified

by the on-site government meat inspector and meets all the USDA

requirements.

Remove and discard as much sinew as possible from the meats. The dimensions

of the grind will depend upon the style of salami you wish to make; for

example,

Meats that are chopped or are a medium or large grind can be mixed fairly

aggressively since the final product will not have a homogeneous texture of

fat to lean. However, the fat in fine ground pastes can become

excessively smeared during the mixing and blending stage if it is not kept

very cold. Of the many variables in making salami, one of the most important

is the temperature of the fat and the meats. The meats used in salami making

should be kept at a temperature range of 36°F to

Sugar:

Essential to the process of making fermented dry cured sausages is the

presence of sugar in the form of glucose (often called dextrose). Glucose

is a sugar that contains carbon hydrogen and oxygen atoms with the general

formula of C6H12O6

The lactic acid bacteria (LAB) get their name from the fact that they

convert glucose to lactic acid, which in turn lowers the pH in the meat

mixture. This has the effect of inhibiting the growth of less

desirable bacteria. Sugar in animal muscle is in the form of a starch

called glycogen and is not immediately available to the bacteria as a food

source so glucose must be added to get the process going; however, other

carbohydrates may also be added in some formulations such as maltodextrin,

lactose or sucrose. All these carbohydrate can easily be broken down into

glucose by LAB.

GLUCOSE

[

LACTIC ACID + ENERGY

C6H12O6

[

2 CH3-CHOH-COOH + 2 ATP

Salt: The

salt is essential because it is involved in the biochemical activities we

call curing as well as the inhibition of some microorganisms found in the

meat. Because LAB are salt tolerant, they get a jump start over less

desirable salt intolerant microorganisms. Contrary to common belief, it is

the salt the only ingredient that is essential to "cure" or preserve the

meat, not the nitrite/nitrate "curing salts". The salt makes the proteins

in the meat soluble, causing a sticky film (myosin) to form around the fat

particles which in turn creates a stable emulsion. The addition of salt to

the meat alters the osmotic pressure of the muscle cells and causes the

dehydration of the meat paste which also prevents growth of food-spoilage

microorganisms. The use of salt alone would produce a harsh, dry and

overly product with an undesirable dark color, therefore other additive to

the meat paste help improve the appearance and taste of the product. The

usual amount of salt added is generally between 2-3% by weight.

Nitrite:

In

addition to the salt, nitrite is added for the inhibition and the

selection certain bacteria found in the meat. In dry cured products, a

mixture of both nitrite and nitrate are added to the meat. As stated on

the "INTRODUCTION" page, it is desirable to select and add lactic acid

producing bacteria to the salami paste. more on this topic follows. You

sometimes see formulas that call for saltpeter (potassium nitrate).

Saltpeter concentration is difficult to control in small amounts and it is

very easy to overdose. The current trend is to move away from saltpeter

and use sodium nitrite/nitrate mixtures. In reality, the nitrate, to be

useful in curing, must be converted to nitrite...this is accomplished by

bacteria (Micrococcus, for example) present in the meat paste.

Nitrite is used up quickly in the curing process so a mixture of nitrate

and nitrite is added to dry-cured meats to ensure a supply of nitrite in

the later stages of maturation. In addition it keeps the meat an appealing

red color. Nitrite reacts with myoglobin and is an essential for the

development of characteristic red color in preserved meats. It is

quickly used up so another sodium compound (nitrate) is added along with

the nitrite. An enzymatic reaction (caused by nitrate reductase)

converts nitrate to nitrite. The reductase is produce by a common

bacterium (Micrococcus) found in the meat or the bacteria may be added

during production.

nitrate reductase

Sodium nitrate

[

Sodium nitrite

Na+ [NO3]-

[

Na [NO2]-

The nitrite is particularly effective in the inhibition of Clostridium

bacteria, which causes botulism.

This microorganism produces a very powerful neurotoxin (nerve poison)

that is the most toxic of all naturally occurring substances. The incidence of the disease is low, but the disease is of considerable

concern because of its high mortality rate if not treated immediately and

properly.

When it is ingested it causes paralysis. if left untreated

12 or more hours, the lungs can be paralyzed and death occurs. Botulism is usually associated with

consumption of the toxin in food. It can exist as a living organism or

spore in contaminated food. The animals most commonly

affected are wild fowl and poultry, cattle, horses and some species of

fish. Sausages, meat products, canned vegetables and seafood products have

been the most frequent vehicles for human botulism. The organism is very resistant to

heat and other treatments. Because naturally occurring levels of spores

are low, cellular growth is required to produce the toxin. C.

botulinum can

grow under the

anaerobic (no oxygen) conditions found in dry-curing sausages and salami. The neurotoxin is heat labile and can be destroyed if

contaminated foods are heated at 80°C (176oF) for 10 minutes or

longer.

Starter Cultures:

Many foods that we enjoy, such as, cheeses, yogurt, beer, and sourdough

bread to name a few are the result of bacterial fermentation. The lactic

bacteria used in salami making are salt tolerant and produce lactic acid

from the glucose (dextrose) in the meat paste, which has the effect of

lowering the pH (or raising the acidity).

I recommend the use of a starter culture in order to control the myriad of

microorganisms that may be present in ground meat, especially

food-spoilage and pathogenic microorganisms. The purpose for using them in

my opinion is twofold: they enhance product safety and enhance product

quality. The environment of the meat is quickly acidified making it a

hostile place for pathogenic and spoilage bacteria to grow. The rapid

increase in acidity inhibits the water bind ability of the meat and makes

for a more consistent drying process. See the discussion of water-activity

(Aw) in the "TIPS" page.

Starter cultures can be difficult to find in small quantities. At one time

they were available only for commercial use, but now they are now

available in small packets for the home sausage maker. I currently use a number of freeze dried starter cultures produced by Chr.

Hansen North America. They are available from several sausage making

suppliers and can be purchased over the internet. Each type produces

slightly different subtle flavors and can be used through a specific range

of incubating temperatures.

I’ve used several species Pediococcus, Staphlococcus, and

Lactobacillus. These microorganisms are available in various mixtures

and I refer you to the charts on my "INTRODUCTION" page. My choices are

based on their optimum incubation temperature

and flavor production. I like Bactoferm LHP whose optimum growth is

obtained between 80-100ºF. It contains a mixture of Pediococcus

acidilactici and Pediococcus pentosaceus).

Bactoferm F-RM-52 shows optimum growth between 70-90ºF.

It is a fast acidifier that is a mixture of

Lactobacillus sakei and Staphylococcus carnosus.

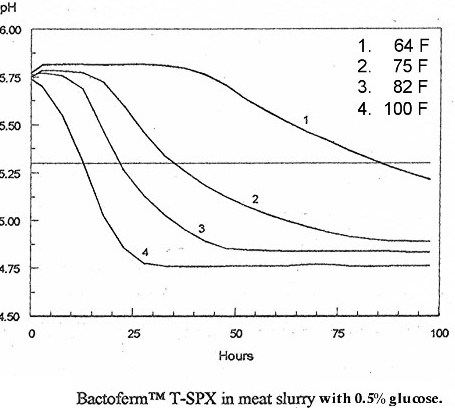

Bactoferm T-SPX is my favorite for northern Italian style salami and shows

optimum growth at 75oF. It is a mixture of

Pediococcus pentosaceus

and

Staphylococcus xylosus). The

Lactobacillus and Pediococcus in these last two mixtures are

the acid producers and the Staphlococcus is the flavor and nitrate

reductase producer.

Spices:

The purpose of the spices is to impart the

desired the taste and aromas that the salami maker prefers. These aromatic

plant substances can be used in their natural form, oils or extracts and

give color or flavor to the product. They can be used whole, cracked or

ground. Spices like garlic and pepper contain antioxidants and help

prevent rancidity. In the majority of the cases, Italian salami is often

flavored with black pepper, cracked or ground, wine infused with crushed

garlic, red pepper or fennel seeds. Other formulations may have mace,

cinnamon, clove or nutmeg. It is absolutely essential that you use fresh

spices for consistent results. If your ground spices are

more than 6 months old, through

them out and purchase new ones. It is always better to

purchase whole, un-ground spices and grind them yourself as

needed...you'll be surprised by the difference!

The meat paste is stuffed into casings and tied. The casing used must

allow moisture to escape the salami throughout the manufacture. The

choices for casings are astonishing. They fall into two categories:

natural and artificial. The artificial casings can be collagen (some

edible others not) or fibrous; the natural can be intestine, bladder,

stomach or esophagus from beef, pork or sheep. In Europe, horse and

donkey innards can also be used in some countries.

For salami, I prefer to use a natural casing called a "beef middle". The

size I use makes salami of 2-1/2 inches in diameter, stuffed. They are

packed in salt and will keep for many months in the refrigerator. I like

to use natural casing for two reasons: they give the salami an "old world"

look and because the are edible, they contribute to the overall taste of

the salami. I also believe the salami dries more evenly and consistently

with natural casings. If you're going to spend money for casings,

you might as well get the kind you can eat! The advantage of

artificial casings are that they are easy to store, they are a consistent

size, and they don't smell!

The Maturation

Process:

In my opinion, the maturation of salami can be thought of being subdivided

in three distinct phases: Curing, Incubating, Drying...all

of which require different temperatures and relative humidity conditions.

Depending upon the type of product that is intended, this process may last

21 or more days

Once the

meat is ground or chopped and all the additives have been added and mixed,

the maturation process of salami production can be thought of being

subdivided in three distinct phases: Curing, Incubating

(Fermentation), and Drying (Aging); each of these phases

require different conditions of temperatures and relative humidity.

Depending upon the type of product that is intended, this process may last

21 or more days. |

So many steps are involved in producing a successful product

that you must keep written records relating the meat to fat ratio, size of

the grind grinder plate, temperature, etc. If you have access to a pH meter

or pH paper, it is helpful to record the pH at this time and again after

fermentation is complete. There are many types of pH papers on the

market. Be sure to get one with a narrow range for a more accurate

reading...generally the best are measure pH from 4.5 through pH 7.5 (5.5-8.0

is OK) Prices vary a lot but you shouldn't have to pay more than $6 a roll!

These notes will be invaluable in evaluating the final product The

preparation of the meat paste begins with grinding the raw materials.

So many steps are involved in producing a successful product

that you must keep written records relating the meat to fat ratio, size of

the grind grinder plate, temperature, etc. If you have access to a pH meter

or pH paper, it is helpful to record the pH at this time and again after

fermentation is complete. There are many types of pH papers on the

market. Be sure to get one with a narrow range for a more accurate

reading...generally the best are measure pH from 4.5 through pH 7.5 (5.5-8.0

is OK) Prices vary a lot but you shouldn't have to pay more than $6 a roll!

These notes will be invaluable in evaluating the final product The

preparation of the meat paste begins with grinding the raw materials.